Posted June 16th, 2017 at 1:27 pm by Sales Team

1: How much does a high lift kit cost?

A custom high lift from DDM typically costs $350 – $500. This does not include an operator; with an operator the cost is $900 – $1100. In addition to the kit cost, expect shipping costs of $50 – $150. Sometimes the shipping cost may be more if the kit is pre-assembled or includes extra hardware. Note: these price ranges are estimates, NOT guarantees.

2: How long does it take to receive the high lift kit?

On average, DDM receives 20-25 high lift inquiries every week. When we receive an inquiry, we look it over and judge based on our 35 years of experience, whether there are any measurements or specs of concern. We will often contact customers if something looks unusual so as to confirm that we have all of the correct information. If the measurements are reasonable, and the customer contacts us soon after receiving the email quote, the turn-around time can be as quick as 1-2 days. Once the kit ships from our warehouse, shipping time within the lower 48 states is usually 1-4 business days. Expect longer transit time for Hawaii/Alaska, or if shipping internationally.

3: How high can I mount my high lift assembly?

Our custom high lift program designs each high lift assembly with the shaft mounted four inches away from the ceiling and jamb. This is to allow sufficient space for the standard high lift cable drum which has an outer diameter of almost 6″. This will place your horizontal tracks 7.75″ – 8.75″ away from the ceiling. On assemblies with more than 54″ of high lift, the horizontal tracks will be closer to 10″ away from the ceiling because they require even larger drums. In reality, the tracks can usually extend another inch or two without any problem. However, we cannot guarantee the door will operate without issue.

https://ddmgaragedoors.com/blog/2016/01/11/high-lift-how-high-can-i-go/

4: What does it mean to have a “balanced door”?

A “balanced door” is one that stays on the floor when closed. It remains at rest when in the middle of its travel and stays up when opened fully. This will be the case if you have the correct springs that are wound the correct number of turns. If your springs are correct, but you still have problems balancing the door, you can usually adjust the springs accordingly, up to ½ turn in either direction. If you still have balance issues, check the cable timing on the drum. On a high lift assembly with the correct cables installed, the cable should begin wrapping on the flat portion of the drum as the top roller of the door begins rolling on the horizontal tracks. If your cable does not perform this way, then the cable is either too short or the installation was not proper.

https://ddmgaragedoors.com/blog/2015/11/03/a-balanced-garage-door/

5: Can I reuse the springs from my previous application?

Most customers understand that standard length cables will need to be changed out for longer cables on a high lift assembly. However, it’s a common misconception that the springs can be reused. Because the vertical portion of the door travel is now extended, there is not an immediate weight offload into the horizontal tracks. The springs need additional turns to account for the extra distance and extra stationary weight (see question 6). However, simply applying more turns to your current springs will not work. This is because the force of the springs will be too great when the door is in the closed position, and it will not close all the way. Instead, you need to purchase springs that are specifically sized for the new setup.

https://ddmgaragedoors.com/blog/2015/11/12/common-high-lift-problems/

6: Why do high lift systems require more turns on the springs?

When the door is in the open position on a standard lift setup, almost 100% of the door weight is sitting in the horizontal tracks. This allows the springs to be almost fully unwound. There is about ½ turn on the springs just to hold tension on the cables. Once a high lift kit is installed, and the tracks are modified, the door will be still only open to just past the opening. Instead of sitting fully horizontal, a portion of the door will be held in a vertical position. Therefore, a percentage of the door weight still needs to be held by the springs. The new larger springs, requiring additional turns, hold this extra weight. Depending on the amount of high lift installed, it could be as much as 2-4 extra full turns. This is also a reason that the previous springs cannot be reused (see question 5).

https://ddmgaragedoors.com/blog/2015/12/11/how-many-turns-do-you-wind-a-torsion-spring/

7: Can I reuse the drums from my previous application?

You cannot reuse your old drums. The resting weight of the door will stay constant for the first few feet of travel. This is due to the longer vertical travel in a high lift kit assembly. But as soon as the springs start unwinding, they begin to lose force. The tapered ends of the high lift drums account for this by proportionally decreasing the moment arm as the springs unwind. Therefore, helping the door stay balanced throughout this vertical extension. The flat portion of the high lift drum is then used as the weight of the door is offloaded into the remaining horizontal track (see question 4). Standard lift cable drums are completely flat, and therefore the moment arm doesn’t change.

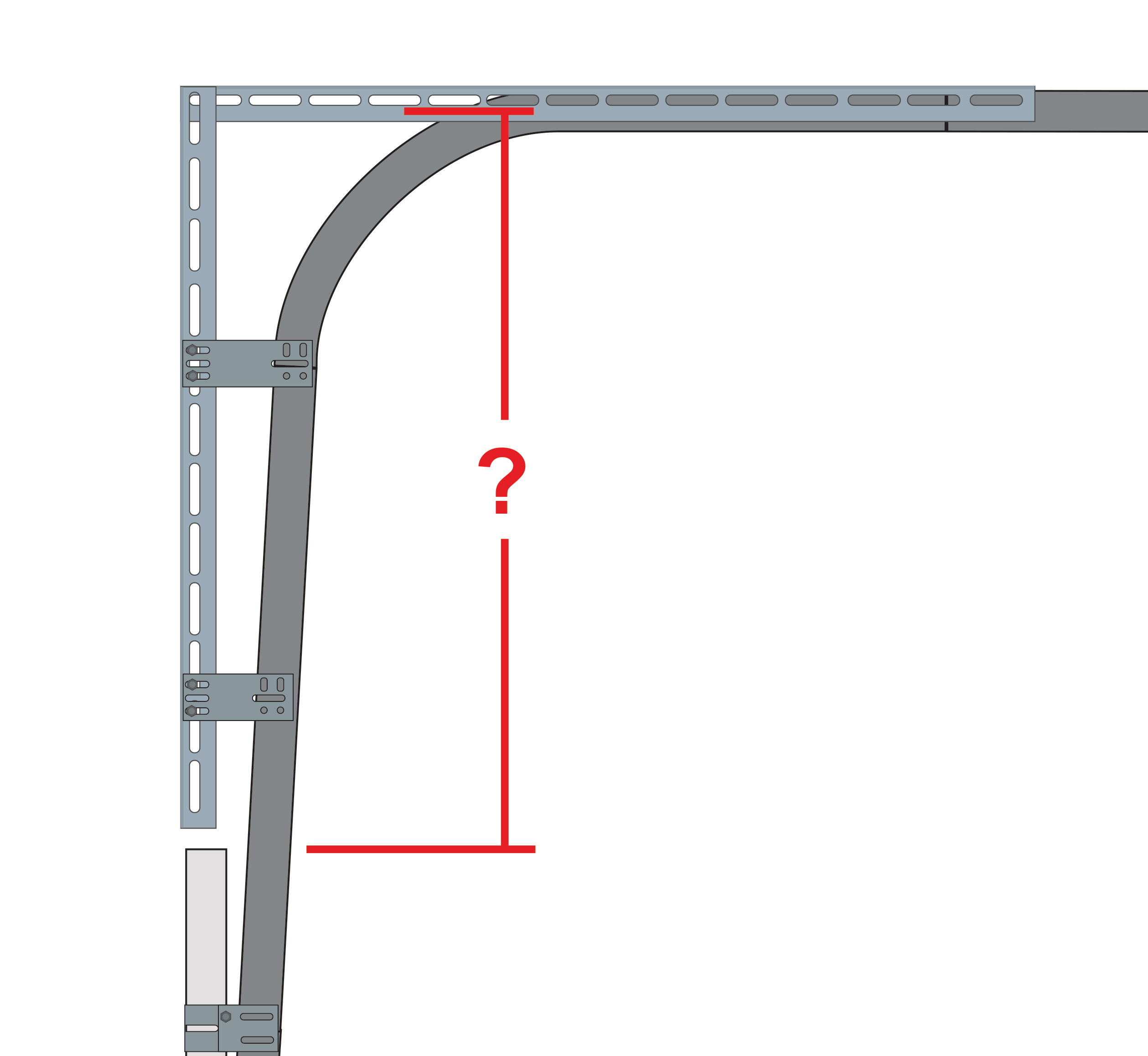

8: Why is my track extension shorter than the inches of high lift?

A common point of confusion for high lift customers is the fact that the track they are adding to the vertical (track extension) does not seem to reach the ceiling. In reality, there are two dimensions, the length of the track extension, and the inches of high lift. The “inches of high lift” (see photo above) is the distance between the top of the closed door and the centerline of the horizontal track, as a flat plane. Therefore, even standard lift systems technically have a few “inches of high lift.” The vertical track extension just adds to this dimension, placing the tracks as close as possible to the ceiling. The track extension simply adds to the inches of high lift; it is not equal to it.

9: I purchased a high lift kit in the last few years. Why are my cables fraying?

Back in 2015, we came across an issue with the high lift cable drums having rough edges. It appears like the seams in the molds used for casting these drums leave behind these rough edges. While the rough edges do not compromise the drums in any way, over time, the installed cables can get worn down and start fraying. We have been working with customers that purchased high lift kits during this time to get the cables replaced and to fix the drums to avoid future issues. Grind down the rough edges with a hand file or angle grinder. The drums can still be used without issue. Before we ship the drums with a kit, we make sure to grind down the rough edges. Please contact us if you still run into this fraying problem.

https://ddmgaragedoors.com/blog/2015/11/16/rough-edges-on-high-lift-drums/

10: Is a vertical lift a good alternative to a high lift?

The appropriate answer is, “Which one do you need?” While high lift doors rise a given distance vertically before entering the horizontal tracks, vertical lift doors rise vertically for their entire travel. These doors do not require horizontal tracks because they rest above the door opening and “parallel” to the jamb. A vertical lift is typically the better option when there is sufficient ceiling height within the garage. The minimum ceiling height for a vertical lift is double the door height, i.e. 14′ ceiling for a 7′ tall door, etc. If the space is available, a vertical lift is a good long-term option to allow maximum space for lighting, workshop equipment, or storage.

https://ddmgaragedoors.com/blog/2011/10/13/vertical-lift-a-good-alternative-to-high-lift-garage-door/

11. How do I keep the windows from scraping the stop molding?

The door will no longer pitch immediately into the track radius as it opens. Therefore, the track for a door with windows may require adjustment so as to avoid scraping the glass against the PVC stop molding or header. If you have windows installed on the door, in order to avoid the need for adjustment after installation, select the option in our high lift inquiry form that you have an outside lock or handle that you want to keep. This will provide the added pitch you need.

https://ddmgaragedoors.com/blog/2016/02/08/gaps-on-high-lift-doors-with-windows/

12: What if I have low headroom tracks currently?

If you have low headroom tracks currently but sufficient headroom for a high lift assembly, then you can modify the tracks to fit the high lift assembly using the parts we provide. You will need to separate the two-track pieces in order to reuse the lower horizontal track and radius. We will provide the standard horizontal track angle to connect the track to the high lift angle. You will probably need to replace the top and bottom fixtures as well.

https://ddmgaragedoors.com/blog/2016/03/15/converting-from-double-low-headroom-tracks-to-high-lift/

This entry was filed under About DDM, Customer Input, How Garage Doors Work. You can follow any responses to this entry through the RSS 2.0 feed.

August 27th, 2024 at 8:42 pm

Sort, I believe I will need high lift drums and cables as well. I will send you measurements when you contact me.

Thanks.

August 29th, 2024 at 8:56 am

We provide a complete high lift kit designed to modify an existing standard lift to the maximum height within the space. You can receive a quote on that kit through this link: https://ddmgaragedoors.com/parts/high-lift/custom-garage-door-high-lift-conversion-kit-quote.php

If you have already modified your track, please give us a call and we can calculate what springs you need.